- September 25, 2025

Rubber beading, often overlooked but critically important, plays a pivotal role in various industries, ensuring efficiency, durability, and safety. From automotive to construction and electrical applications, rubber beadings serve as sealing agents, shock absorbers, and protective barriers. Behind these essential components are skilled manufacturers dedicated to delivering high-quality rubber solutions.

What is Rubber Beading?

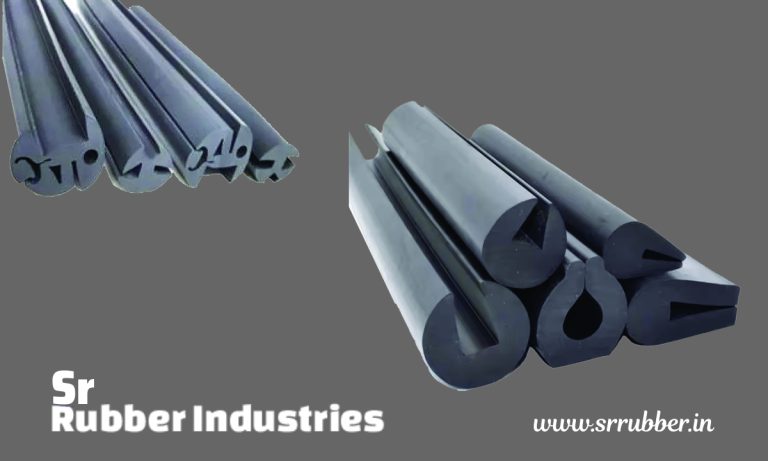

Rubber beading is a versatile material used primarily as a sealing or protective element. Made from high-grade rubber compounds like EPDM, silicone, or natural rubber, these beadings are designed to withstand harsh environmental conditions, including extreme temperatures, UV exposure, and chemical resistance. Commonly used in industries like automotive, railways, and construction, rubber beadings provide insulation, prevent dust and water ingress, and minimize vibration.

The Role of Rubber Beading Manufacturers

Rubber beading manufacturers are at the forefront of innovation, crafting customized solutions for diverse industrial needs. Their expertise lies in developing products that meet stringent quality standards while offering tailored dimensions, shapes, and material compositions to suit specific applications. These manufacturers prioritize precision, durability, and environmental sustainability in their processes.

Key Features of Quality Rubber Beadings:

Industries Benefiting from Rubber Beadings

Key Attributes of Leading Rubber Beading Manufacturers

Choosing the Right Rubber Beading Manufacturer

Selecting the right manufacturer is critical to ensure product reliability and performance. Here are a few tips:

Why Rubber Beadings Are Indispensable

The versatility and durability of rubber beadings make them indispensable across industries. Whether in sealing a car door, protecting sensitive electrical equipment, or enhancing the energy efficiency of a building, these components deliver unmatched performance. Their ability to adapt to challenging environments while maintaining functionality underscores their importance in modern manufacturing and construction.

Conclusion

Rubber beading manufacturers are the backbone of many industries, providing essential components that ensure safety, efficiency, and durability. By investing in advanced technology, sustainable practices, and customer-centric solutions, these manufacturers are shaping the future of industrial applications. Whether you’re in the automotive, construction, or electronics industry, partnering with a trusted rubber beading manufacturer is key to achieving quality and reliability in your projects.

S R Rubber Industries is a trusted name in rubber beading manufacturing, recognized for its quality, innovation, and customer-first philosophy. Whether you are in the automotive, construction, or industrial sector, their robust and reliable products are designed to enhance performance and efficiency.

Choosing S R Rubber Industries as your rubber beading manufacturer means partnering with a company that values excellence, sustainability, and your success. Experience the difference with S R Rubber Industries and elevate your projects with the best in the industry.

For inquiries or more information, connect with S R Rubber Industries today!

Copyright © Srrubberindustries 2017. All rights reserved.

Designed by: Star Web Maker